One of the most highly utilized valve types in an extensive list of applications, solenoid valves work to actively dose, mix, distribute, shut off, or release fluids in high-purity fluid transfer applications. iPolymer dedicates our business to the international distribution of quality, high-purity fluid handling equipment for companies in a vast array of professional industries. We offer multiple chemical resistant solenoid valves to meet your unique needs.

Miniature and Sub-Miniature Chemical Resistant Solenoid Valves

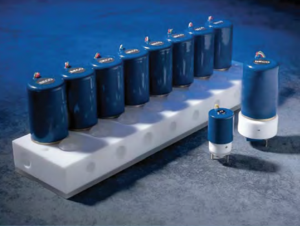

Robust material choices and designs allow iPolymer miniature and sub-miniature solenoid valves to offer impressive performance, under extreme chemical conditions. Configured as two-way and three-way valves, these high-purity valves work to electromechanically control fluid flow between multiple channels and ports. All iPolymer miniature chemical resistant solenoid valves can be customized with four different internal body configurations, and five different methods for seat sealing, with our sub-miniature options offering four internal body configurations and three methods for seat sealing. Intended for pharmaceutical, semiconductor, chemical processing, and biomedical industries, all of our chemical resistant solenoid valves are built with a virgin PTFE wetted surface design for maintaining high levels of purity.

Robust material choices and designs allow iPolymer miniature and sub-miniature solenoid valves to offer impressive performance, under extreme chemical conditions. Configured as two-way and three-way valves, these high-purity valves work to electromechanically control fluid flow between multiple channels and ports. All iPolymer miniature chemical resistant solenoid valves can be customized with four different internal body configurations, and five different methods for seat sealing, with our sub-miniature options offering four internal body configurations and three methods for seat sealing. Intended for pharmaceutical, semiconductor, chemical processing, and biomedical industries, all of our chemical resistant solenoid valves are built with a virgin PTFE wetted surface design for maintaining high levels of purity.

In addition to having multiple configurations available for our chemical resistant solenoid valves, iPolymer can custom design features like specialized port connection types, manifolded valve assemblies, longer wire leads (38”or 48”), and various power management options.

In addition to having multiple configurations available for our chemical resistant solenoid valves, iPolymer can custom design features like specialized port connection types, manifolded valve assemblies, longer wire leads (38”or 48”), and various power management options.

iPolymer staffs some of the best industry professionals to help you find the perfect high-purity fluid transfer part or system for your business. Our chemical resistant solenoid valves are trusted in a number of industrial, chemical, and biomedical processing applications around the world. Invest in our long-term, high-performance fluid transfer solutions today! . Give us a call at 435.783.6040 or request a free quote.