Discover iPolymer’s Range of Chemical Resistant Valves

Finding secure, dependable valves for use with corrosive chemicals can be a challenge. These valves must be tough enough to withstand contact with substances that can destroy other materials while providing reliable, low-maintenance performance.

iPolymer manufactures a range of chemical-resistant valves that provide a cost-effective, efficient solution suitable for use in many industries.

Discover iPolymer’s Range of Chemical Resistant Valves

We offer a wide selection of chemical-resistant values to meet your requirements.

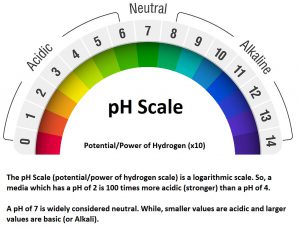

From a design standpoint, chemical-resistant valves are pretty much any type of valve that offers good performance in chemical applications. More common commodity valves, manufactured from low-grade plastic, steel or aluminum, will not hold up against high and low pH chemistries. When the media (liquid or gas) has a corrosive nature, such as, sulfuric acid, the application calls for a chemical-resistant valve.

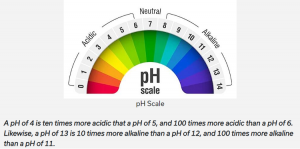

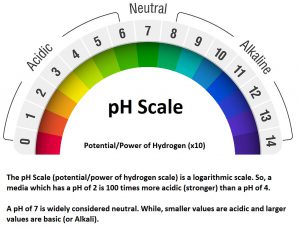

An acid rated at pH 2 is much more corrosive than a mild acid with a pH of 5. In fact, 1,000 times. Unfortunately, it isn’t quite this simple, but 0, 1, 2 and 12, 13, 14, you are most likely going to use PTFE devices. Mild pH 5, 6, 8, 9, you can use polypropylene or PVC devices. Raw PTFE material cost 350% more than polypropylene and PVC.

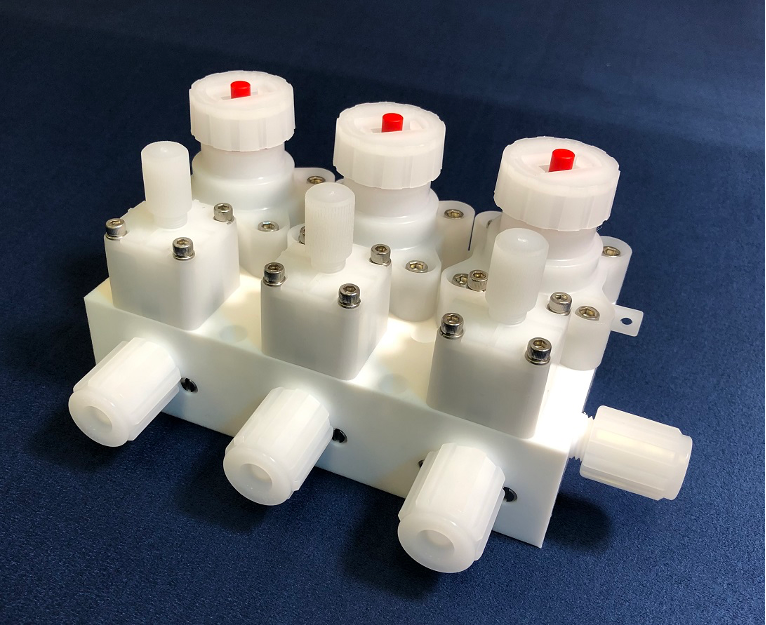

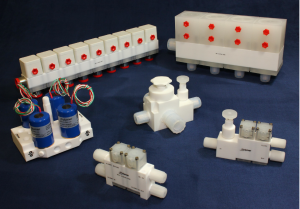

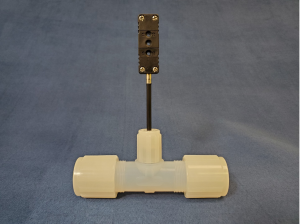

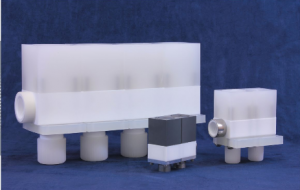

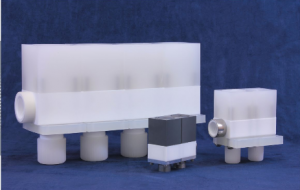

The iPolymer Chemical-Resistant Valve product line, also known as our CR Valve product line, is a specific design configuration. Our CR Valve line is a linear manifold family of valves, which can be configured with one inlet and up to 13 outlets (or the reverse: one outline and up to 13 inlets). One inlet feeding up to 13 outlets would be considered a distribution configuration. One outlet fed by up to 13 inlets would be considered a selection configuration.

iPolymer’s Chemical Resistant Valve line offers chemical and corrosion control through its complete fluoroplastic design and construction. All wetted surfaces are manufactured from virgin PTFE. Pneumatic actuators, bases and bands are constructed from polypropylene (standard) and PVC (custom).

The polymer components selected for our CR Valve line are specifically suited for use with ultrapure water, deionized water, solvents, chemicals and liquid flowing biomatter. Our PTFE bellows-style valve stem and PTFE valve seat ensure the valve self-flushes a wide variety of flowing media.

Special custom configurations are available on request. These include: manifold valve assemblies with multiple ports and high-ambient temperature pneumatic actuators. Using our configuration application, you also can select material, number of ways, and port size and type, among features.

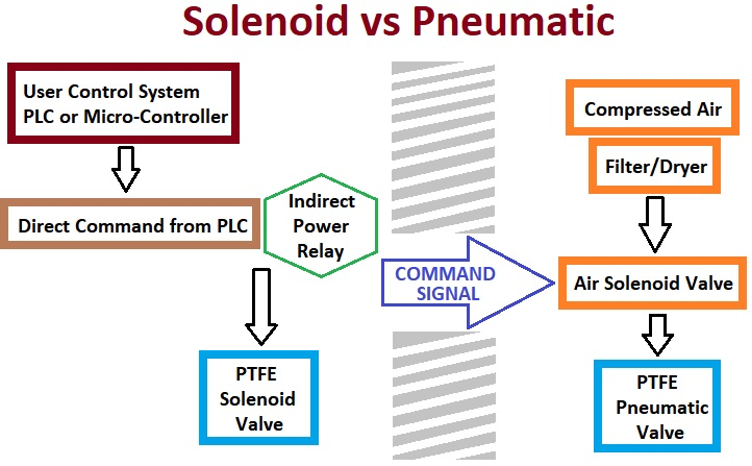

iPolymer’s Miniature Solenoid Valve series includes 2- and 3-way valves with a variety of body configurations, seat-sealing methods and solenoid coils. The all-PTFE wetted flow path design is optimized for ultra-clean and chemical applications. Their design is ideally suited for semiconductor, pharmaceutical, biomedical and chemical process applications.

iPolymer Miniature Solenoid Valves, with a 100% wetted flow path, offer precision performance under extreme conditions. We also can custom configure these valves for specific requirements, including; vacuum applications and unique manifold configurations.

Configurable with an EPDM, Viton, Aflas, or Kalrez O-Ring, or PTFE hard seat, the iPolymer Miniature Series PTFE Solenoid Valve line provides unsurpassed chemical compatibility with a wide range of flow media.

Highlights:

- PTFE design optimized for ultra-clean and chemical compatibility;

- Fast, accurate and repeatable coil response time;

- High-duty cycle rated with controlled ambient temperatures;

- Valve seat and diaphragm for positive flushing and tight shut off;

- Nonporous diaphragm to isolate solenoid coil from media;

- O-ring seat configurations for vacuum and complex media applications;

- Designed for aggressive media and elevated temperatures.

Subminiature Solenoid Valves

The iPolymer Subminiature Solenoid Valve line—offered in 2-way NC, 2-way NO and 3-way designs—perform under extreme conditions. The all-PTFE wetted surface design is suitable for a wide range of ultra-clean to highly corrosive media applications—making them ideally suited for semiconductor, pharmaceutical, biomedical and chemical process applications.

The standard valve includes a PTFE body, stem and diaphragm, but our subminiature line also is available with PEEK and Polypro bodies. Four port orientations are available for 3-way valves. Configuration options for the O-ring seat seals are EPDM, Viton, Aflas and Kalrez. Maximum recommended duty cycle is 62%.

Highlights:

- PTFE design for ultra-clean and chemical compatibility;

- Available for DC & AC voltages;

- Fast, accurate and repeatable coil technology;

- Diaphragm designed for positive flushing;

- Nonporous diaphragm isolates coil;

- Designed for aggressive media and elevated temperatures.

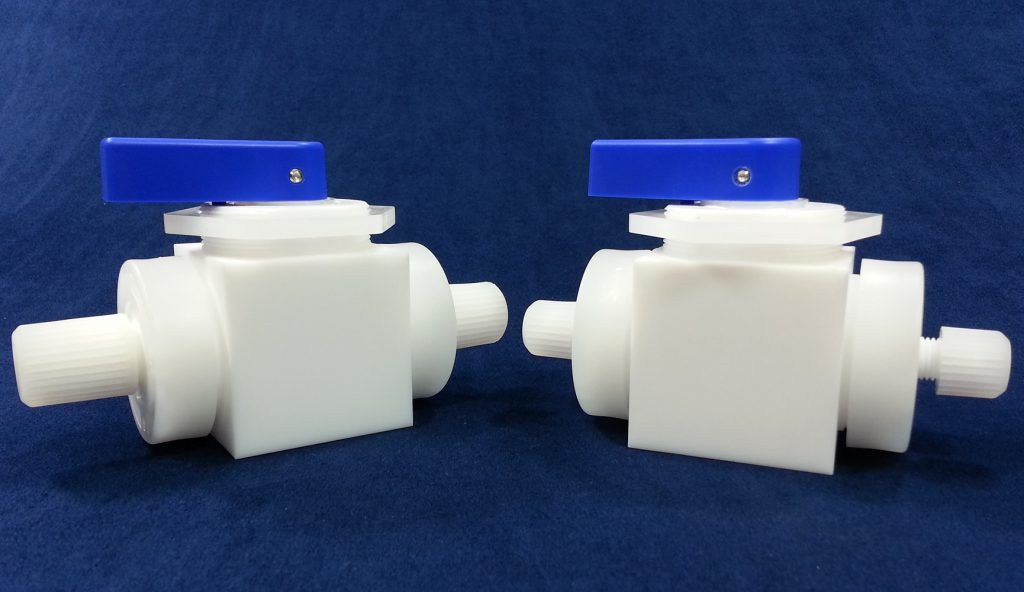

PTFE Ball Valves

iPolymer’s Check Valve series features all-PTFE-wetted surfaces for excellent performance in all high-purity applications given the design resists chemical corrosion and other elements within harsh process environments. Our check valves are commonly found as backflow preventers in clean processes. Please contact us with your special application requirements. PEEK, PVDF and polypropylene configurations are available upon request.

iPolymer’s Precision Plug line offers precision machined manual control valves with all-PTFE wetted surfaces and PVDF stem nut, allowing for operation with harsh chemicals and ultra-clean deionized water. The single-through orifice with a tapered body matches the tapered plug for positive shutoff. Various orifice and port sizes are available as standard items. Other sizes and configurations are available on request. Our Precision Plug Valve are supplied in two configurations: Straight Flow Pattern (“A”) and Angled Flow Pattern (“B”).

iPolymer’s Metering Valve line uses a tapered plug-stem to offer fine adjustment to flow as well as fully open or fully closed shutoff position. The PTFE all-wetted surface design works equally well with ultra-clean deionized water and harsh chemical media. As with all metering valves, we recommend filtering the media before it enters the valve. Our metering valves come in two configurations: Straight Flow Pattern (“A”) and Angled Flow Pattern (“B”).

iPolymer Stopcock Valves offer all-wetted PTFE design, making them ideal for chemical fluid and gas-flow shutoff applications and well-suited for clean room and deionized water applications. Stopcocks are a simpler version of our popular ball valves. The handle points in the direction of flow. By rotating the quarter turn handle/stem, the stopcock partially meters flow.

iPolymer Manual Diaphragm Valves are design for manual actuation of our popular Pneumatic and Solenoid configured Miniature Diaphragm Valves. Offered as 2-way PTFE Valves, these are similar to our Precision Plug Valves. Rather than a stem plug, this valve offers a flexible diaphragm hard-seat seal operated by hand and is used where pneumatic and electrical connections are not practical or not necessary. iPolymer diaphragm valves provide unsurpassed chemical compatibility with a wide range of media. The all-wetted PTFE body, valve stem and one-piece diaphragm maintain a material inert boundary for ultra clean applications.

The iPolymer PTFE Sampling Metered Valve is designed for use in high-purity water and aggressive chemical applications. This unique manual actuated metering valve is design for low-flow sampling. The PTFE wetted flow path is ideal for deionized water systems and corrosive media found in solar, semiconductor, pharmaceutical and chemical process applications. This panel mount unit functions with a manual push level to actuate metered flow to ensure controlled dispensing for manual sampling. Uses include dispensing controlled amounts of media for element verification tests, manual dispensing of deionized water into carboy and other transport containers, and dispensing metered amounts of chemicals to blend and balance process chemistries.

iPolymer Miniature Pneumatic Diaphragm Valves offer precision performance under extreme conditions. Options include 2- and 3-way valves with four body configurations and three valve seat sealing methods. The flow path is virgin PTFE for excellent chemical resistance and high-purity integrity.

Our iPolymer PTFE Pneumatic Valve line features an all-PTFE wetted surface design ideally suited for harsh chemical and corrosive media and environments, as well as clean room and deionized water applications. The pneumatic actuator housing is designed into the main valve body for use within wet bench and extreme pH applications, such as:

- acid parts cleaning

- chemical delivery

- chemical neutralization

- deionized water rinse

- phosphoric acid nitride removal

- potassium hydroxide etching

- sulfuric peroxide stripping

- wafer etching

At iPolymer, we pride ourselves on supplying the best chemical-resistant valves available. We offer a great selection in addition to a highly knowledgeable staff who can help you find exactly what you need. Give us a call at 435.783.6040 or request a free quote.